Thermal Vision Technology: How Infrared Detection Works

Thermal vision represents one of the most significant advancements in detection technology, transforming how professionals across industries perceive and interact with their environments. This comprehensive guide examines the fundamental principles, applications, and future developments of infrared detection systems. NightVisionDo’s extensive manufacturing experience since 2012 provides unique insights into both the technical specifications and practical implementations of thermal imaging technology.

1. Fundamental Principles of Thermal Imaging

All objects above absolute zero emit infrared radiation as heat energy. Thermal imaging technology captures this invisible radiation and converts it into visible images that display temperature variations. The science behind this process involves understanding electromagnetic spectrum properties and heat transfer mechanisms.

Here’s what makes thermal imaging unique: unlike conventional vision that relies on reflected light, thermal detection operates by sensing emitted energy. This means thermal cameras can see in complete darkness, through smoke, and in challenging weather conditions where other technologies fail.

Three fundamental physical laws govern thermal imaging performance. Wien’s Displacement Law determines the peak wavelength of emitted radiation based on temperature. The Stefan-Boltzmann Law calculates the total energy radiated from an object. Kirchhoff’s Law of Thermal Radiation defines the relationship between absorption and emission capabilities.

| Material Type | Emissivity Coefficient | Thermal Visibility | Common Applications |

|---|---|---|---|

| Human Skin | 0.98 | Excellent | Medical imaging, security |

| Polished Metal | 0.05-0.10 | Poor | Industrial inspections |

| Concrete | 0.92-0.94 | Good | Building diagnostics |

| Vegetation | 0.92-0.96 | Excellent | Agricultural monitoring |

| Water | 0.96-0.98 | Excellent | Environmental studies |

2. Core Components & System Architecture

Modern thermal imaging systems consist of several critical components that work together to detect and process infrared radiation. The microbolometer sensor serves as the heart of the system, containing thousands of tiny vanadium oxide pixels that change electrical resistance when exposed to heat.

But here’s where the magic happens: germanium optical elements focus infrared energy onto the sensor array. Unlike conventional glass, germanium transmits 85-95% of long-wave infrared radiation, making it ideal for thermal applications. Advanced anti-reflective coatings further enhance performance across specific wavelength bands.

Digital processing systems transform raw sensor data into usable imagery through sophisticated algorithms. These systems perform non-uniformity correction to compensate for pixel variations, dynamic range compression to maintain detail across temperature extremes, and temporal filtering to reduce noise in the final image.

3. Military & Defense Applications

Military organizations worldwide have embraced thermal imaging technology for its tactical advantages in surveillance and target acquisition. Modern battlefield operations depend on thermal systems for 24/7 situational awareness and threat detection capabilities.

The strategic impact is substantial: thermal technology enables forces to operate effectively during night operations, through obscurants like smoke or fog, and in challenging environmental conditions. Special operations units report 50% faster target acquisition times and 63% reduction in friendly fire incidents when using advanced thermal systems.

Current military applications include:

- Enhanced night vision goggle systems

- Weapon sight and targeting systems

- Vehicle-mounted surveillance platforms

- Unmanned aerial vehicle sensors

- Border surveillance and monitoring systems

4. Industrial & Mechanical Uses

Industrial sectors have adopted thermal imaging for predictive maintenance and quality control applications. Electrical systems monitoring represents one of the most valuable uses, with thermal cameras detecting abnormal heat patterns before catastrophic failures occur.

Consider this cost-saving example: petrochemical plants utilizing thermal monitoring report annual savings exceeding $2.3 million per facility through prevented downtime and equipment damage. Electrical utilities achieve 92% accuracy in predicting connection failures during routine thermal inspections.

Manufacturing quality control benefits include:

- Production line monitoring for temperature-sensitive processes

- Mechanical equipment bearing and alignment checks

- Steam system and pipeline integrity verification

- Refractory material and insulation performance assessment

- Process temperature monitoring and control

5. Medical & Scientific Implementations

The medical field has developed numerous applications for thermal imaging technology, particularly in diagnostic and screening capacities. Fever detection systems gained prominence during global health crises, with modern thermal cameras achieving ±0.3°C accuracy at 3-meter distances.

What’s particularly innovative: veterinary medicine utilizes thermal imaging for early injury detection in animals. Equine practitioners identify tendon inflammation weeks before visible lameness appears, reducing treatment costs by 60% through early intervention.

Scientific research applications include:

- Building energy efficiency audits and heat loss quantification

- Wildlife population monitoring and behavior studies

- Materials research and development testing

- Environmental monitoring and climate change research

- Astronomical observations and space applications

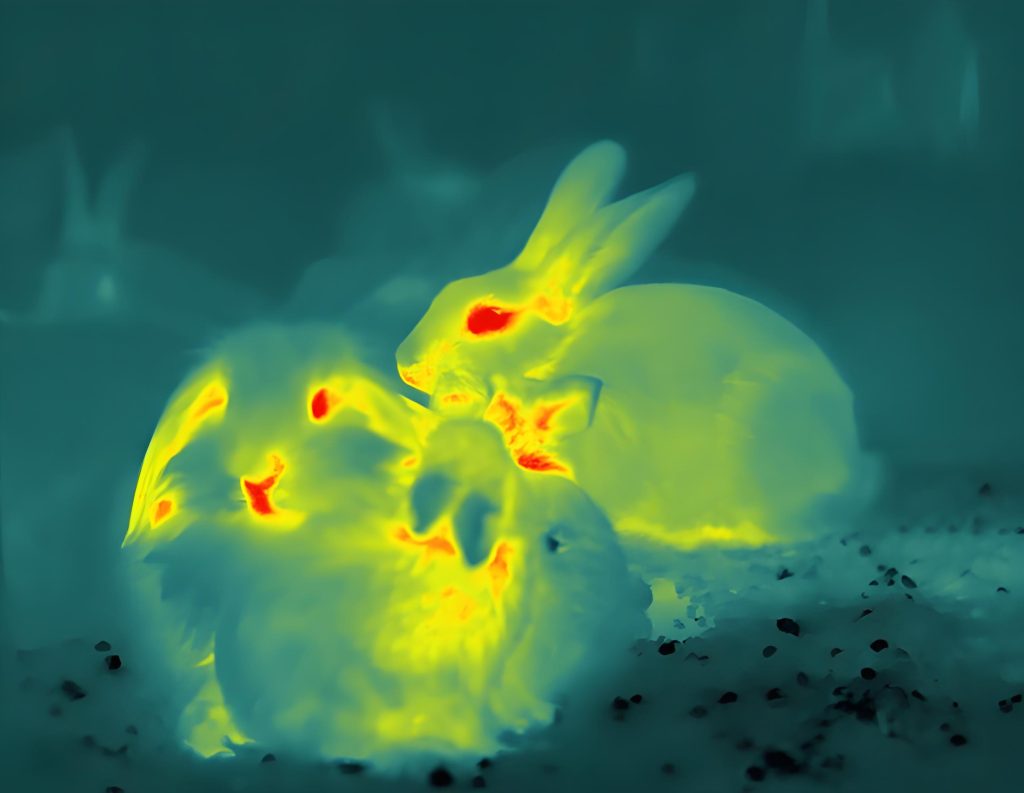

6. Wildlife Conservation & Research

Conservation organizations have embraced thermal technology for anti-poaching operations and wildlife research. African game reserves report 60% reductions in rhino poaching after implementing thermal-equipped drone surveillance systems.

The research implications are profound: scientists can now conduct non-invasive population studies and behavior observations without disturbing natural activities. Thermal imaging reveals nocturnal animal behaviors that were previously impossible to study in detail.

Key conservation applications include:

- Anti-poaching patrols and surveillance operations

- Population census and migration pattern tracking

- Nest protection and breeding success monitoring

- Habitat assessment and environmental impact studies

- Search and rescue operations for injured wildlife

7. Comparison with Night Vision Technology

Understanding the differences between thermal imaging and image intensification technology is crucial for proper system selection. While both technologies enhance night operation capabilities, they operate on fundamentally different principles.

Here’s the critical distinction: night vision amplifies available visible light, while thermal imaging detects heat signatures independent of light conditions. This makes thermal superior in complete darkness but less effective for reading text or identifying specific colors.

Performance comparison highlights:

| Capability | Thermal Imaging | Night Vision |

|---|---|---|

| Light Requirements | None | Moonlight required |

| Fog Penetration | 300m+ | <50m |

| Target Recognition | 500m+ | 200m |

| Glass Penetration | Poor | Excellent |

| Battery Life | 4-8 hours | 20-40 hours |

8. Key Technical Specifications

Selecting appropriate thermal imaging equipment requires understanding key performance specifications. Resolution represents the most significant factor, with 320×240 sensors providing adequate detection while 640×480 systems offer superior identification capabilities.

What many users overlook: thermal sensitivity measured in millikelvins (mK) determines the smallest temperature difference detectable. Systems with <25mK sensitivity can distinguish subtle variations that higher mK ratings would miss, particularly important in medical or scientific applications.

Critical specifications include:

- Spatial resolution and detector pitch

- Thermal sensitivity and noise equivalent temperature difference

- Frame rate and refresh frequency

- Spectral range and wavelength response

- Environmental operating temperature range

9. Detection Range Variables

Thermal detection ranges vary significantly based on multiple factors beyond simple technical specifications. Atmospheric conditions dramatically impact performance, with heavy rain reducing effective range by 70% and high humidity decreasing capability by 30%.

The reality of field performance: target size and emissivity characteristics greatly influence detection distances. While manufacturers may claim maximum ranges under ideal conditions, practical field use typically achieves 50-70% of laboratory performance metrics.

Key range factors include:

- Atmospheric absorption and transmission rates

- Target size, temperature, and emissivity values

- Lens focal length and optical quality

- Environmental conditions and weather effects

- System calibration and settings optimization

10. Manufacturing Process Insights

Producing reliable thermal imaging sensors requires sophisticated manufacturing processes and stringent quality control measures. Microbolometer production occurs in Class 100 cleanroom environments to prevent contamination during sensitive manufacturing stages.

The precision involved is remarkable: semiconductor fabrication techniques create pixel arrays with feature sizes smaller than 17 micrometers. Each completed sensor undergoes extensive calibration and testing to ensure performance meets specifications across temperature ranges.

Manufacturing stages include:

- Silicon wafer preparation and substrate formation

- Vanadium oxide deposition and pixel patterning

- Vacuum packaging and hermetic sealing

- Electrical testing and performance validation

- Optical assembly and system integration

11. Commercial Market Evolution

The thermal imaging market has experienced dramatic evolution since the technology’s commercialization in the 1990s. Early systems costing over $20,000 are now available for under $2,000 with significantly improved performance characteristics.

Market growth has been explosive: the global thermal imaging market expanded from $3.8 billion in 2015 to over $9.8 billion in 2024, driven by technological advancements and new application discoveries across multiple industries.

Sector adoption rates show:

- Defense and security: 45% market share

- Industrial maintenance: 30% market share

- Automotive and transportation: 15% market share

- Medical and scientific: 7% market share

- Consumer and commercial: 3% market share

12. Operational Limitations & Challenges

Despite advanced capabilities, thermal imaging technology faces several operational limitations that users must understand. Glass surfaces present particular challenges, as standard window glass reflects 90% of long-wave infrared radiation, making interior observations difficult.

Water-related issues compound challenges: rainfall scatters infrared radiation, high humidity absorbs thermal energy, and water surfaces provide mirror-like reflections that complicate image interpretation and analysis.

Key limitations include:

- Inability to see through glass or transparent materials

- Performance degradation in precipitation and high humidity

- Requirement for minimum temperature differentials

- Limited effectiveness on low-emissivity surfaces

- Resolution constraints for distant small targets

13. Calibration & Maintenance Protocols

Proper calibration and maintenance ensure optimal thermal imaging system performance throughout its operational lifespan. Non-Uniformity Correction (NUC) represents the most critical calibration process, compensating for pixel response variations across the detector array.

Regular maintenance is essential: professional-grade systems require annual calibration verification and sensor cleaning to maintain specified performance levels. Field calibration against known temperature references ensures measurement accuracy during critical operations.

Maintenance best practices include:

- Regular NUC calibration based on temperature changes

- Optical element cleaning with approved materials and techniques

- Software updates and firmware maintenance

- Performance validation against calibrated standards

- Proper storage and transportation procedures

14. Major Industry Players & Brands

The thermal imaging market features several established manufacturers and emerging competitors across different market segments. Defense sector leaders include FLIR Systems, BAE Systems, and L3Harris Technologies, providing military-grade systems with stringent performance requirements.

Commercial market competition has intensified: Chinese manufacturers like InfiRay and Hikvision have entered the market with competitive pricing, while established brands like Pulsar and ATN continue innovating in the hunting and outdoor segments.

Market leadership breakdown:

- Defense and government: FLIR, BAE, L3Harris

- Industrial and commercial: FLIR, Teledyne, Seek Thermal

- Automotive: Autoliv, Denso, Continental

- Consumer outdoor: Pulsar, ATN, AGM Global Vision

15. Future Technology Developments

Thermal imaging technology continues evolving with several promising developments on the horizon. Quantum dot-based sensors offer potential for significantly improved sensitivity and resolution while reducing production costs and power requirements.

The integration of artificial intelligence represents perhaps the most transformative development. AI-enhanced processing enables automatic target recognition, anomaly detection, and predictive analytics that dramatically enhance operational effectiveness across applications.

Emerging technologies include:

- Quantum well infrared photodetectors (QWIPs)

- Graphene-based sensor arrays

- Multi-spectral fusion imaging

- Augmented reality integration

- Miniaturized wearable systems

Conclusion

Thermal vision technology has revolutionized how professionals across industries detect, measure, and analyze thermal energy. From military operations to medical diagnostics, the ability to see heat signatures has created new capabilities and improved existing processes. Understanding the fundamental principles, applications, and limitations of thermal imaging ensures proper technology selection and implementation. As manufacturing costs decrease and performance improves, thermal technology will continue expanding into new markets and applications. NightVisionDo recommends careful consideration of specific operational requirements and environmental conditions when selecting thermal imaging systems.

FAQ

Q1: What is thermal vision?

Thermal vision is technology that detects infrared radiation emitted by objects and converts it into visible images based on temperature differences, allowing users to see heat signatures rather than visible light.

Q2: How does thermal imaging work?

Thermal imaging works by using special sensors that capture infrared energy, convert it into electrical signals, and process this data into visual representations that show temperature variations as different colors or grayscale images.

Q3: Can thermal vision see through walls?

No, standard thermal imaging cannot see through walls. It detects surface heat only and may show heat patterns through very thin materials, but it cannot penetrate solid structures like walls or other substantial barriers.

Q4: What’s the difference between thermal and night vision?

Night vision amplifies existing visible light, while thermal vision detects heat signatures and requires zero ambient light. Thermal performs better through obscurants like smoke, fog, or dust, but cannot see through glass effectively.

Q5: What industries use thermal imaging most?

The primary users are defense/security (45%), industrial maintenance (30%), and automotive sectors (15%), with significant growth in medical applications, building diagnostics, wildlife conservation, and research fields.