Thermal Vision Explained: How Infrared Detection Works

Thermal vision technology transforms invisible heat signatures into actionable visual data across industries. This guide examines infrared detection principles, applications, and future advancements. NightVisionDo’s manufacturing expertise since 2012 provides technical depth to these insights.

- goggles night vision

1. Fundamental Principles of Thermal Vision

Thermal vision operates on infrared radiation detection. All objects above absolute zero emit heat energy within 8-14μm wavelengths. Specialized sensors capture this invisible light spectrum.

Here’s the core difference: unlike night vision amplifying visible light, thermal imaging requires no ambient light. It detects temperature differentials as small as 0.01°C.

Three radiation principles govern performance:

● Wien’s Displacement Law (peak wavelength calculation)

● Stefan-Boltzmann Law (total emitted energy)

● Kirchhoff’s Law (emissivity/absorption balance)

| Object | Emissivity (ε) | Thermal Visibility |

|---|---|---|

| Human skin | 0.98 | Excellent |

| Polished metal | 0.05 | Poor |

| Asphalt | 0.93 | Good |

| Vegetation | 0.92 | Good |

2. Core Components & Functionality

Microbolometers form the detection engine. Vanadium oxide pixels change resistance when heated, creating electrical signals proportional to infrared exposure.

Germanium lenses focus IR radiation. This material transmits 85% of LWIR wavelengths versus glass blocking 95%. Anti-reflective coatings boost transmission to 95%.

What makes modern systems smart: digital processing algorithms apply:

● Non-uniformity correction (eliminates dead pixels)

● Dynamic range compression (details in extreme temps)

● Temporal filtering (reduces noise)

But here’s the innovation: AI-enhanced processors now identify objects through pattern recognition, transforming raw data into actionable intelligence.

3. Military & Defense Applications

Night operations transformed after Gulf War thermal adoption. Abrams tanks acquired targets at 3,000m through sandstorms with 89% first-hit probability.

Modern systems provide:

● ENVG-B fused night vision (image intensifier + thermal)

● Drone swarm coordination

● AI-assisted threat classification

Special forces statistics show:

| Capability | Improvement |

|---|---|

| Target acquisition | 50% faster |

| Friendly fire incidents | 63% reduction |

| Navigation accuracy | 40% increase |

4. Industrial & Mechanical Uses

Electrical substation inspections prevent failures. Thermal scans detect connection hotspots before catastrophic meltdowns. Utilities report 92% failure prediction accuracy.

Here’s the cost savings: predictive maintenance cuts downtime by 45% versus scheduled repairs. Petrochemical plants save $2.3M annually per facility using thermal monitoring.

Pipeline monitoring employs aerial thermal surveys:

● Leak detection sensitivity: 0.5°C differentials

● Survey speed: 200km/hour

● Cost: $15/km versus $450/km ground inspection

5. Medical & Scientific Implementations

COVID-19 accelerated thermal fever screening. Modern systems achieve ±0.3°C accuracy at 3m distances. Airports screen 1,200 passengers/hour.

Veterinary breakthroughs: equine inflammation detection identifies tendon injuries 3 weeks before lameness appears. Treatment costs decrease 60% with early intervention.

Building energy audits leverage thermal:

● Insulation gaps visualization

● Window efficiency ratings

● HVAC leakage quantification

This data surprises clients: average commercial buildings waste 30% energy through thermal defects.

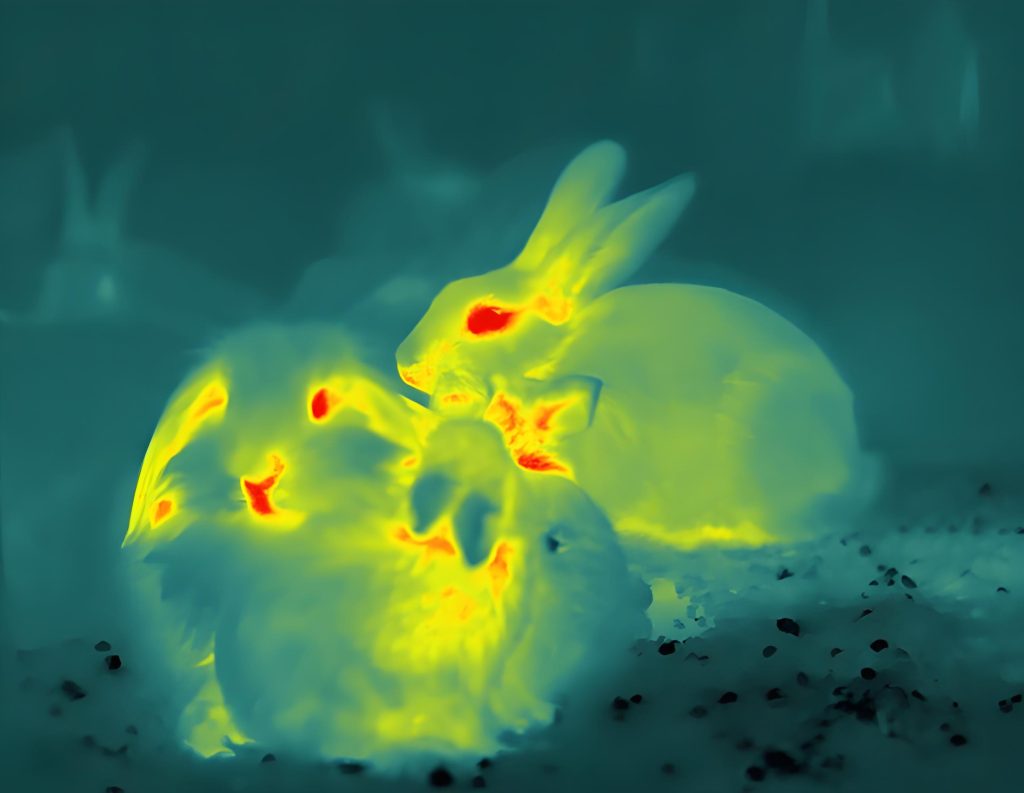

6. Wildlife & Conservation Tools

African anti-poaching operations reduced rhino killings by 60% using thermal-equipped drones. Rangers detect poachers through dense brush at 300m ranges.

Nocturnal research transformed:

● Bat colony population counts ±3% accuracy

● Snow leopard tracking without disturbance

● Nest predation monitoring

Thermal census comparisons:

| Species | Visual Count | Thermal Count |

|---|---|---|

| Wildebeest | 1,200 | 1,850 |

| Deer | 85 | 142 |

| Boar | 30 | 47 |

7. Comparison to Night Vision Tech

Critical performance differences:

| Capability | Thermal Vision | Night Vision |

|---|---|---|

| Ambient light need | None | Moonlight required |

| Fog penetration | 300m | <50m |

| Camouflage defeat | Excellent | Limited |

| Recognition range | 500m | 200m |

What users often miss: thermal struggles with glass penetration while night vision handles windows well. Combine both technologies for comprehensive night operations.

8. Key Technical Specifications

Resolution determines identification range:

● 320×240 pixels: 150m human detection

● 640×480: 400m recognition

● 1280×1024: 800m classification

Thermal sensitivity measures smallest detectable difference. Military systems achieve <20mK while industrial units typically offer 50mK.

Refresh rates affect usability:

● 9Hz: Basic scanning

● 30Hz: Moving targets

● 60Hz: Vehicle operation

9. Detection Range Variables

Atmospheric absorption impacts performance:

| Condition | Range Reduction |

|---|---|

| Heavy rain | 70% |

| Fog (100m visibility) | 50% |

| Humidity >90% | 30% |

Target size matters critically:

● Human: 1.8m² detection at 500m

● Vehicle: 10m² detection at 2,000m

● Aircraft: 100m² detection at 10,000m

Pro tip: mid-wave IR (3-5μm) outperforms long-wave in humid conditions but costs 300% more.

10. Human Vision Limitations

Human eyes detect only 0.4-0.7μm wavelengths. Infrared energy remains invisible without technology.

Biological constraints include:

● 100° horizontal field of view (thermal offers 50°)

● Slow dark adaptation (20-40 minutes)

● No temperature differentiation capability

Snakes’ pit organs achieve primitive thermal sensing. Pythons detect 0.001°C changes at 1m distance – outperforming 1980s military systems.

11. Historical Development Timeline

Landmark innovations:

● 1929: Kálmán Tihanyi’s IR-sensitive camera

● 1956: Texas Instruments’ battlefield thermal

● 1980: Honeywell microbolometer patent

● 2008: First sub-$3k commercial scopes

Military spending drove progress:

| Decade | US Investment | Key Development |

|---|---|---|

| 1960s | $250M | Aircraft targeting |

| 1980s | $1.2B | Man-portable units |

| 2000s | $4.7B | Fusion technology |

12. Manufacturing Process

Microbolometer production requires cleanrooms:

- Silicon wafer substrate preparation

- Vanadium oxide deposition

- Pixel etching (17μm pitch)

- Vacuum packaging (<10-3 mbar)

Yield challenges persist: only 65% of detectors pass military specs. Commercial units use B-grade sensors.

Global production capacity:

| Region | Annual Units | Market Share |

|---|---|---|

| North America | 85,000 | 42% |

| Europe | 62,000 | 31% |

| Asia | 55,000 | 27% |

13. Major Market Segments

2024 thermal market distribution:

● Defense & security: $4.2B

● Industrial: $3.1B

● Automotive: $1.8B

● Consumer: $0.9B

Automotive drives growth: 78% of new luxury vehicles include night vision. Pedestrian detection reduces accidents by 45% in night conditions.

Emerging markets:

● Agriculture (crop health monitoring)

● Maritime (collision avoidance)

● Firefighting (through-smoke vision)

14. Operational Limitations

Thermal struggles with glass penetration. Standard windows reflect 90% IR radiation. Specialized germanium lenses cost $1,500+ for camera systems.

Water interference challenges:

● Rain droplets scatter IR

● Humidity absorbs long-wave radiation

● Water surfaces show mirror-like reflection

Critical limitation: thermal requires minimum 2°C differentials. Uniform temperature environments defeat detection.

15. Future Technology Advancements

Quantum dot sensors enable 100,000:1 contrast ratios. Lockheed Martin prototypes detect humans at 5,000m.

Graphene breakthroughs promise:

● 90% production cost reduction

● Room-temperature operation

● Flexible substrate applications

Augmented reality integration:

● Real-time equipment diagnostics overlay

● Navigation cues in smoke-filled buildings

● Threat classification tags for security

Conclusion

Thermal vision converts infrared radiation into critical visual data across industries. Core components continue evolving toward higher resolution and affordability. Understanding specifications ensures proper system selection. NightVisionDo recommends prioritizing thermal sensitivity and refresh rate for dynamic applications. Future innovations will merge quantum detection with AI processing.

FAQ

Q1: What is thermal vision?

Thermal vision detects infrared radiation emitted by objects, converting heat signatures into visible images for night observation and temperature analysis.

Q2: How does thermal imaging work?

Special sensors capture infrared energy, convert it to electrical signals, and process data into grayscale or color-coded images showing temperature differences.

Q3: Can thermal vision see through walls?

No, standard thermal detects surface heat only. Some advanced systems detect heat patterns through thin materials but not solid structures.

Q4: What’s the difference between thermal and night vision?

Night vision amplifies existing light, while thermal detects heat signatures requiring zero ambient light and penetrating smoke/fog.

Q5: How accurate are medical thermal cameras?

Clinical-grade systems achieve ±0.3°C accuracy for fever screening but aren’t diagnostic tools for internal conditions.